Products

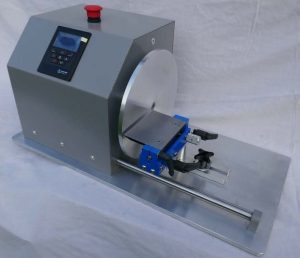

Vertical belt sander for watchcase refinishing

Left is a typical example of what we currently offer but the exact spec spec is tailored to suit the customer’s requirements. Belt can be mounted either to the right of machine (as above) or to the left

Left is a typical example of what we currently offer but the exact spec spec is tailored to suit the customer’s requirements. Belt can be mounted either to the right of machine (as above) or to the left

Example and guide price with this specification, 75 x 1065 belt size, (option of 50, 75 or 100 wide belts) rubber coated bottom drive wheel,75 x 50 top crowned aluminium tracking roller(as per belt size), Gas tension system 1 Hp variable speed zero to 1500 rpm 240 volt single phase domestic supply

Fully enclosed motor / inverter with panel mounted control panel, emergency switch, voltage in supply at rear via 3 pin plug/socket, Machine mounted on an aluminium base, Up and over belt guard, machine painted in a mid-grey, comes complete with a worm and wheel type table

Delivered, installed and demonstrated (within the UK only) within 250 miles

Guide price for the above with 75 mm belt is £2775

Please note the price quoted is for guidance only and depending on the specification could go up or down, please call or email to discuss your requirements

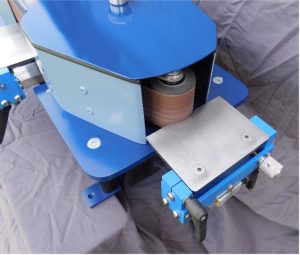

Single disc lapping machine

Single disc lapping machine, can be tailored to your requirements.

Single disc lapping machine, can be tailored to your requirements.

Example and guide price with the following specification.

1 x disc, 240 mm diameter x 10 mm thick aluminium centrally mounted via a countersunk 8 mm socket head screw, so they are easy to change, (spare discs can be supplied at extra cost) it is also available with double sided disks allowing abrasive to fit on both sides of the disk as a consequence the double sided disk has a 40 mm x 3 mm button in the middle.

1 Hp variable speed, 240 volt domestic supply, fully enclosed motor / inverter with panel mounted control panel, emergency switch, voltage in supply at rear via 3 pin plug/socket.

Machine mounted on an aluminium base.

1 x 18 mm silver steel rail exit main frame. Worm and wheel type table supplied with quick release system.

Machine painted mid grey.

Delivered, installed and demonstrated (within the UK only) within 250 miles

Guide price for the above £2375

Please note the price quoted is for guidance only and depending on the specification could go up or down, please call or email to discuss your requirements.

Twin Disc Lapping Machine for Watchcase Refinishing

Left, is a typical example of what we currently offer, the exact spec is tailored to suit the customer’s requirements.

Left, is a typical example of what we currently offer, the exact spec is tailored to suit the customer’s requirements.

Example and guide price with the following specification

2 x discs, 240 mm diameter x 10 mm thick aluminium centrally mounted via a countersunk 12 mm socket head screw, easy change, discs at 25 mm overlap and 5 mm gap between discs (spare discs can be supplied, extra cost).

1 Hp variable speed, 240-volt domestic supply, fully enclosed motor / inverter with panel mounted control panel, emergency switch, voltage in supply at rear via 3 pin plug/socket.

Machine mounted on an aluminium base.

2 x 18 mm silver steel rails exit main frame length and diameter as per customer requirements.

Comes complete with ONE worktable, which can be swivelled over to the other disc, for a twin worktable set up please add £500.

Machine painted to customer requirements.

We can also off the same as above but in a slightly smaller enclosure with a more rounded appearance and reversable discs (or standard discs) (see below)

We can also off the same as above but in a slightly smaller enclosure with a more rounded appearance and reversable discs (or standard discs) (see below)

Delivered, installed and demonstrated (within the UK only) within 250 miles

Guide price for the Twin Disc is £4285

Please note the price quoted is for guidance only and depending on the specification could go up or down, please call or email to discuss your requirements.

If you are interested in the rounded case please phone for initial discussion on specification to ensure we meet your needs.

Combination machine, belt sander and disc sander the COMBO

Combination machine, belt sander and disc sander the COMBO

Left, shows a typical example of some of what we currently offer, belt sander can have 25 mm, 50, 75 or 100 mm belts x 1065 or 1000 long, lower pulley is 100 mm diameter rubber coated so can be used as a contact wheel, discs up to 240 mm diameter in aluminium, permanently mounted or interchangeable with spare discs are available, I can also offer double sided discs the compromise is there is a button 40 x 3 mm in the middle, belt sander can be mounted either to the right or left of the machine with the disc on the opposite end, there is a choice of platens either steel or at a slightly greater cost glass, machine is mounted onto a base plate with am 18mm diameter rail for a trolly (not supplied) , supplied with two worm and wheel type tables finished in a colour of your choice

Motor is 1 x Hp fully enclosed with inverter and remote-control panel 240 volt single phase fitted with emergency stop button

Price for the above varies with the specification as an example the above fitted with 75 mm belt and a single 240 mm disc, 2 x worktables £3750

Please contact to discuss pricing and specifications

Extra discs @£90 each

Vertical mount for belt end table @£50

Single straight colour for finish free, metallic, pearls etc at cost, extra colour @£20

Delivered, installed and training free of charge within a 250 mile radius of Newbury a small fuel charge will apply for greater mileages.

Horizontal belt machine with interchangeable wheels,

Overall specification, 1Hp variable speed 0 – 1500 rpm single phase 240 volts, belt size 50 x 1065 overall length aprox 550mm width 360 mm depth to mounting points 200 mm (overall depth 400 mm) small wheel head with 5 x interchangeable rollers 16 mm to 25 mm plus 6 x inch flat work area worktables adjustable for depth and angle, fully guarded except for work areas

roller end showing one of the rollers fitted and the table with small cut out

flat work area with a worm and wheel type table, adjustable for depth and angle.

The unit uses an Invertek Optidrive inverter it’s a standalone unit mounted in a position that suits the end user

Pricing and options, as a guide the price for the above machine as a ready to use package delivered (within 250 miles of RG20) installed and operator training, IMPORTANT please be aware that they must be mounted on a substantial work surface that will require a cut out for the motor to go into so its mounted at its correct position, alternatively a lower worktable with extended machine legs will be required this is due to the motor being mounted under the machine

Current price for machine as shown with variable speed £2995

As I’m sure you appreciate these are built to order and therefore have a build time, as a guide its approximately 6-8 weeks from receiving an order and deposit which is currently £300 I am happy to discuss any special requirements that you may have to suit your particular needs please feel free to phone or email.

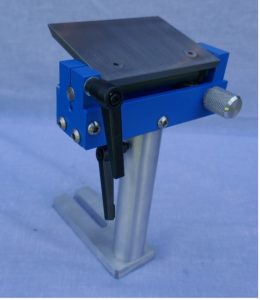

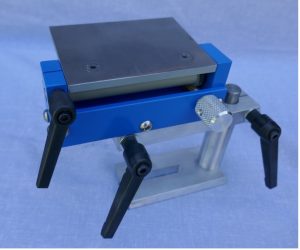

Tables for watchcase refinishing and other applications, I currently offer tables that use a worm and wheel adjustment system, they are extremely accurate and robust, a complete quick release mounting system is available to suit your requirements.

Tables for watchcase refinishing and other applications, I currently offer tables that use a worm and wheel adjustment system, they are extremely accurate and robust, a complete quick release mounting system is available to suit your requirements.

Tables are supplied as standard with a 110 x 80 x 6 mm worktable in mild steel, they have a worm and wheel adjustment for angle and when used in conjunction with a digital angle gauge very precise angular settings are possible

Table mounted onto a quick release system enabling very quick adjustments and removal/replacement. Table can be locked in the desired position. Suitable for disc machine applications

Table and quick release system as mounted for a belt machine, suitable for either left- or right-hand machines. Height of the upright should be specified at point of order

Cost of tables, again it very much depends on the specification required but as shown above with a 110 x 80 x 6 mm table either painted or left unpainted mounted onto a quick release system for either a disk or belt application. As an example the ones above complete with quick release system come to £450 please phone or email to discus the quick release system required as the materials required will dictate the overall cost

Phone or email to discuss the specification required